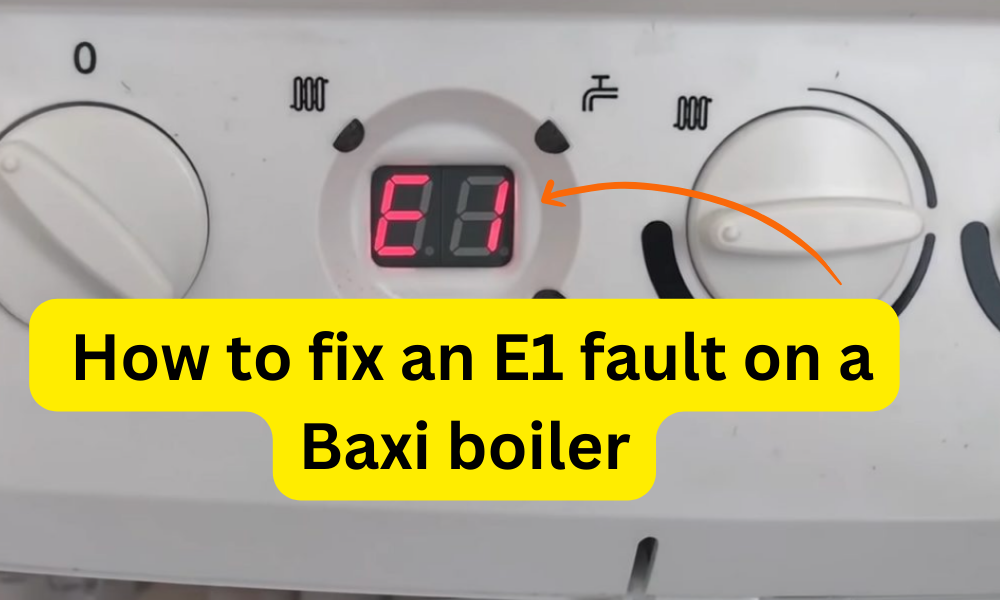

E1 Error on Baxi Boiler

As a homeowner in the United Kingdom, encountering a Baxi boiler displaying an E1 code can be quite unsettling. The E1 error is quite a common issue indicating a sharp drop in water pressure - a situation meaning that my boiler could be overheating or experiencing leaks. I've found that resolving it typically involves repressurising the system. Troubleshooting E1 error on Baxi boiler can often be done independently, saving both time and the cost of calling out a professional. So, if you're confronting the baxi E1 fault, don’t despair—fixing E1 fault on Baxi boiler might be simpler than you think, and I'm here to guide you through the process.

Key Takeaways

- The 'E1 Baxi boiler fault' indicates a drop in water pressure, potentially due to a leak.

- Effective troubleshooting E1 error on Baxi boiler often requires repressurising the boiler to the recommended level.

- Before proceeding with fixing E1 fault on Baxi boiler, ensure the heating system is switched off.

- If the 'E1 code on Baxi boiler' persists after repressurisation, seek professional advice.

- Regularly check your boiler for signs of an E1 fault to circumvent boiler breakdowns and costly repairs.

Understanding the E1 Error on Your Baxi Boiler

When the central heating system begins broadcasting a distress signal in the form of an E1 error, my pulse quickens ever so slightly. This alert from a Baxi boiler does more than just signal an immediate malfunction—it reveals a detailed message meant to guide us through a troubleshooting procedure that can often save us from a cold night or, worse yet, a costly repair. The relationship between homeowner and Baxi boiler hinges on understanding these baxi boiler error codes.

Deciphering the E1 Fault Code

My approach to diagnosing e1 fault on baxi boiler begins with breaking down the distress calls into their specific ailments. For instance, a displayed E119 translates to low water pressure, a mere whisper of protest that can typically be assuaged with repressurisation. E133, a more threatening growl, hints at a gas supply fault, while E168's alarm points to an electrical supply problem. Recognising these codes is like interpreting a language that tells a story of the boiler's internal state of being.

Common Symptoms and Initial Diagnostics

The symptoms accompanying an e1 baxi boiler error often manifest as a flashing display on the boiler's console, an impossible-to-ignore sign commanding immediate attention. It echoes the idea of dashboard warning lights—a symbol-based language developed to convey the urgency of mechanical issues that even the most mechanically uninclined individual can interpret. Suspecting an issue, I begin a preliminary check: scanning the water pressure levels and evaluating whether a simple repressurisation could be the baxi boiler e1 error solution or if a greater problem looms on the horizon, necessitating a skilled hand.

| Error Code | Symptom | Potential Solution |

|---|---|---|

| E119 | Dropping water pressure | Boiler repressurisation |

| E133 | Interrupted gas supply | Ensure gas valve is open, reset boiler |

| E168 | Electrical supply fault | System reset, check circuit |

It is thus, with e1 baxi boiler symptoms in hand, that I arm myself with the knowledge to distinguish between a minor hiccup in the machinery and an imminent need for professional oversight. And it is in this moment, readers, that we recognise the true power of knowing your boiler beyond its warm facade—and the empowerment brought forth by informed troubleshooting.

Step-by-Step Guide to Resolving E1 Error on Baxi Boiler

When my Baxi boiler flashes with the dreaded E1 error, it's usually a clear sign that the water pressure has dropped and it's time for a fix to the E1 Baxi boiler. Thankfully, with a bit of know-how, the repair process is comparatively simple. Let me walk you through a detailed guide to fixing the E1 error on your Baxi boiler, ensuring your home's warmth is restored with minimal fuss.

- Ensure the heating system is turned off – safety first, always.

- Locate the filling loop or header tank – this is your gateway to repressurising the system.

- Adjust the water pressure by slowly opening the filling loop valves – watch the pressure gauge rise.

- Once the gauge reads between 1 and 2 bar, you've hit the sweet spot; it’s time to close the valves.

- Restart the heating system and observe the boiler's response – it should now operate without the E1 code appearing.

I've learnt with experience that the key to a successful baxi E1 fault repair is not just about adjusting the pressure; it's also crucial to check for any underlying issues that might be causing the pressure to drop. Regular maintenance is the best preventative measure, so here's a breakdown of the actions to take following a successful fix:

| Action | Description | Frequency |

|---|---|---|

| Pressure Gauge Check | Monitor the boiler's pressure gauge to ensure it's within the ideal range. | Monthly |

| Valve Inspection | Check the integrity of filling loop valves and seals for any signs of wear or leaks. | Every 6 months |

| Professional Assessment | Have a Gas Safe registered engineer inspect the boiler system to preempt any potential issues. | Annually |

By following this guide to fixing the E1 error on a Baxi boiler, not only do I ensure an immediate resolution, but also ongoing reliability. Remember, careful attention today promises seamless warmth tomorrow.

Troubleshooting E1 Error: Causes and Solutions

As a diligent owner of a Baxi boiler, I have encountered the E1 error, which can cause a fair amount of inconvenience. The manifestation of an E1 error could signal common issues with Baxi boilers that vary from low water pressure to more serious gas or electrical supply faults. Let's embark on a thorough baxi boiler troubleshooting process to understand the nuances of these issues and determine how to address E1 Baxi boiler fault effectively.

Low Water Pressure: Causes and Fixes

One frequent cause of the E1 error is a fallen water pressure, often denoted as E119. Should you discover that the water pressure is below the recommended level—usually between 1 and 2 bar—repressurisation is a straightforward remedy at your disposal. This is how it's done:

- Locate the filling loop beneath the boiler.

- Ensure the heating system is turned off.

- Carefully open the valves and watch the pressure gauge climb.

- Once the gauge indicates the optimal pressure, close the valves.

- Restart the boiler to check if the E1 fault has cleared.

Gas Supply Faults and How to Address Them

Another culprit could be a gas supply issue, typically flagged as an E133 fault. The boiler will cease to operate if it detects no gas supply or encounters a gas blockage. Here are the steps I recommend:

- First check the gas supply to ensure it's turned on and functioning.

- If the supply is active, try resetting the boiler; this often rectifies temporary errors.

- If the fault persists, it's essential to contact a Gas Safe registered engineer for a more in-depth inspection.

The importance of professional assistance cannot be overstated when dealing with gas-related problems, as they can pose significant safety risks.

Electrical Supply Issues - Identifying and Resolving

Lastly, a broad spectrum of electrical supply faults, often indicated by E168, can trigger the E1 error. These are less straightforward to diagnose and resolve but frequently start with a simple reset of the boiler. If tripping or power fluctuations are observed, it's advised to:

- Reset the boiler to see if the issue clears.

- If the fault code returns, inspect other electrical appliances for similar issues to rule out broader electrical problems at home.

- Obtain the expertise of a qualified electrician or heating engineer if the E1 code reappears, as continued electrical issues require a professional approach.

Navigating through the different causes of the E1 error shows the varied nature of their complexities. In my experience, understanding these intricacies not only helps in quick fixes but also in maintaining the boiler's health, potentially preventing recurrence of such issues. Always remember, when in doubt, seeking professional advice is the safest route to ensuring your Baxi boiler returns to its optimum performance.

Maintaining Your Baxi Boiler to Prevent Future E1 Errors

As someone dedicated to preventing Baxi boiler E1 errors, I understand the importance of routine servicing and careful attention to detail. Ensuring your boiler operates within its ideal parameters is critical for avoiding disruptions in your home's heating system. Let me share some baxi boiler maintenance tips to help you preserve the health of your unit.

- Regularly check the pressure gauge to confirm the boiler pressure stays within the recommended range, typically between 1 and 2 bars. Immediate corrections can prevent the E1 error from occurring.

- Perform seasonal maintenance checks to identify any potential issues before they lead to faults, such as the dreaded E1 error.

- Become familiar with your boiler's user guide. Knowledge of your Baxi's operations allows you to spot anomalies and take corrective measures swiftly.

While these steps will significantly aid in maintaining a Baxi boiler, it is also advisable to enlist the help of a professional for an annual service. This ensures all components are in prime condition and can reveal any underlying issues that might not be immediately obvious to the untrained eye.

Maintaining your boiler isn't just about avoiding the inconvenience of error codes; it's about ensuring a consistently warm home and the peace of mind that comes with reliable equipment. Take these maintenance tips to heart, and your Baxi boiler should serve you well for years to come.

When to Seek Professional Help for Your Baxi Boiler E1 Error

Addressing an E1 error on a Baxi boiler is often straightforward, but there are instances where professional intervention becomes essential. It's vital for safety and longevity of your heating system to recognise the signs that indicate a need for qualified baxi boiler assistance.

Recognising Complex Boiler Problems

Some E1 errors on your Baxi boiler can herald complex boiler problems beyond the DIY scope. This includes scenarios where repressurisation has failed to resolve the issue, or you've noticed continuous fluctuation in water pressure despite corrective measures. Signs of corrosion or damage within the boiler system also fall under this category. In such cases, seeking professional help for Baxi e1 fault is the safest route to ensure effective repairs, with minimal risk to you and your home.

Connecting with Qualified Heating Engineers

When it's clear that expert knowledge is required, it's crucial to connect with a baxi boiler engineer who is both skilled and certified to address your heating system's needs. Engineers certified by Gas Safe provide assurance of quality service and are legally authorised to work on gas appliances. They are equipped to handle intricate issues that could be causing the persistent E1 errors. Below is a helpful table to aid in identifying when a Gas Safe-registered engineer's service is necessary:

| Issue Indicator | DIY Troubleshooting | Professional Help Needed |

|---|---|---|

| Recurrent Low Pressure After Repressurising | Check for visible leaks, repressurise if possible | Persistent low pressure after DIY correction |

| Unresolved Error Codes Post-Reset | Attempt a system reset | Error persists post multiple resets |

| Boiler Leakages or Corrosion | Visual inspection for obvious damage | Professional repair or parts replacement |

| Uncertain Electrical Faults | Reset electricity supply and check fuse box | Electrical issues without identifiable causes |

| Gas Supply Interruption | Ensure gas supply is on and check for simple blockages | Direct interaction with gas supply or components |

In conclusion, while some E1 faults may be managed through careful home troubleshooting, certain signs suggest the need for qualified Baxi boiler assistance. For those in the UK facing challenges which require an intricate understanding of boiler systems, it's prudent to engage a Gas Safe-registered engineer without delay.

Conclusion

In summarising the steps required to address the E1 error in a Baxi boiler, we've discovered that rectifying the issue often involves a simple process of repressurising the system. This is an immediate solution that restores functionality to many heating systems, reflecting the **summary of Baxi E1 error solutions** that have been discussed throughout this piece. As I've navigated through troubleshooting techniques, I've endeavoured to present you with information that's not only practical but also easily digestible and executable.

Summarising Quick Fixes for E1 Error

My exploration into this common fault code has highlighted that most instances of the E1 error can be swiftly rectified by reinstating the correct water pressure within your boiler. Indeed, this quick fix is effective but the onus remains upon you, the boiler owner, to regularly monitor and **reflect on Baxi boiler upkeep** to circumvent future disruptions.

Reflecting on Long-term Boiler Health and Maintenance

The longevity and efficiency of your Baxi boiler are intrinsically linked to routine inspections and preventive maintenance. While this guide aids in resolving immediate issues, it's imperative to remember that persistent problems require professional insight. Hence, should you encounter complications surpassing the realm of basic fixes, I advocate consulting a Gas Safe-registered engineer. Such precaution will serve to maintain your boiler's **long-term health**, safeguarding against both inconvenience and unnecessary expenditure.

FAQ

What is an E1 error on a Baxi boiler?

An E1 error code on a Baxi boiler indicates a problem with the water pressure in your heating system, which could be due to a sudden drop or a leak, causing the system to overheat or malfunction. It's crucial to address this promptly to ensure the boiler operates correctly.

How can I fix an E1 fault on my Baxi boiler?

To fix the E1 fault, you will need to repressurise your boiler system. This is done by locating the filling loop or header tank, turning off the heating, and refilling the system to the recommended pressure level, usually between 1-2 bar. After repressurising, restart the heating system and check if the error has been resolved.

What should I do if repressurising does not clear the E1 error?

If repressurising the boiler does not clear the E1 error, it's possible that there may be an underlying issue such as a gas supply fault (E133) or an electrical supply problem (E168). In this case, it is advisable to seek professional help from a qualified heating engineer.

Can a Baxi E1 fault indicate other issues besides low water pressure?

Yes, a Baxi E1 fault code can sometimes indicate issues other than low water pressure, such as problems with the gas supply (E133) or electrical supply faults (E168). Each specific fault code can provide further insight into what might be causing the E1 error.

How do I prevent E1 faults on my Baxi boiler in the future?

Regular maintenance of your Baxi boiler can help prevent E1 faults. This includes monitoring the pressure gauge to ensure the pressure is within the recommended range and addressing any issues promptly. It's also a good idea to become familiar with the boiler's user manual and perform routine inspections.

When should I call a professional to look at my Baxi boiler E1 error?

You should call a professional if you are unable to resolve the E1 error by repressurising the system, or if the error recurs often. Also, for any faults that involve gas supply or complex electrical issues, it's important to consult a Gas Safe registered heating engineer.

Are there long-term benefits to addressing an E1 error promptly on my Baxi boiler?

Yes, promptly addressing an E1 error on your Baxi boiler can have long-term benefits. It can prevent potential breakdowns, enhance the efficiency of your heating system, and extend the lifespan of the boiler. Regular maintenance is key to preventing future issues.